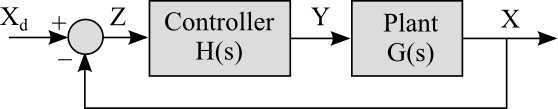

T he goal in control systems design is to change the response of the plant by adding a controller to the system. To simplify the design process there are several standard controller that are commonly used. On this site we focus on industry standard PID and Lead/Lag controllers. Systems that are difficult to control may require a more advanced controller. See a controls textbook for details. On this site we focus on controllers with a unity feedback configuration. However, all of the techniques presented here will work equally well with other controller configurations.

Figure 3.1 shows a block diagram of a control system with unity feedback.

PID stands for Proportional, Integral, Derivative. PID controllers are commonly used in process control applications and for motion control. A PID controller has the form

where x is the input to the controller and y is the output from the controller. The transfer function form of the PID controller is

A PID controller can use any combination of P,I or D. The simplest controller uses only proportional control (kD = kI = 0). Other common configurations are PI, PD and PID control. To determine the value of the constants kP, kI and kD the designer can use a variety of techniques. This site illustrates how to design PID controllers using both Root Locus and Frequency Response methods.

Before formally calculating these gains, its useful to have some intuition about how a PID controller affects system performance. Note that the discussions below are only guidelines and may not apply to all systems.

The simplest controller uses only kP and is called proportional control. In general, kP is used to adjust the bandwidth of the closed-loop system. Increasing kP tends to make the system respond faster.

kD affects derivative control. Derivative control is used to control overshoot and tends to add damping to the closed-loop system. However, high values of kD make the system suseptible to noise.

kI affects the integral portion of the control. Integral control is used to reduce steady-state error (when the output does not follow the input). The disadvantage of integral control is that it tends to slow down the closed-loop response. Integral control can also make a system unstable and may require the addition of proportional or derivative control to stabilize the closed-loop system.

The following experiment lets you adjust the gains in a PID controller and see how they affect system response.

PID Controller

PID ControllerLead/Lag controller are commonly used in electronic devices. A discussion on Lead/Lag controller is currently under development.